- Food Startup Funding: Do you need investors to build a successful food or beverage business? - February 29, 2024

- Explaining Food Certifications & Labeling: Organing, Non-GMO, Halal, Kosher, & More! - February 29, 2024

- Explaining the Meaning of MOQ - February 29, 2024

Whether you’re looking for the next big product for your soda company or just starting to produce your own soft drinks, finding the most suitable manufacturer for your beverage brand can take a lot of effort.

There are plenty of reliable soft drink manufacturing companies out there–which is great–but that makes reviewing their offerings and capabilities a time-consuming process. To help narrow your options, we’ve come up with a curated list of some of the best soft drink manufacturing companies and co-packers in the country.

Where are soft drinks manufactured?

Most soft drinks are made inside the manufacturing plants of independent manufacturers. Independent manufacturers are typically granted licenses to produce the products of popular franchise companies like PepsiCo and Coca-Cola.

With access to the secret formulas of soda drinks, the independent manufacturers are able to follow the procedures and source the ingredients they need for production. Normally, the manufacturers are also responsible for the packaging and distribution process of the products.

Ready to find a contract manufacturer for your soft drink project? Use PartnerSlate.

PartnerSlate streamlines the manufacturing process by matching you with high-quality production partners from our extensive network of food and beverage manufacturers and packagers. Just list your project on the PartnerSlate marketplace and our matching system will connect you with multiple interested co-manufacturers that have the right capabilities to produce your soft drink.

After you’re connected, our platform streamlines document sharing, communication, and onboarding so you can start getting your product right to the shelves.

Soft Drinks Manufacturing Process

Soft drinks are normally produced using a multi-step process and a set of high-purity, food-grade ingredients. Some of the common ingredients used in the production include water, carbon dioxide, sugar, flavors, and acids.

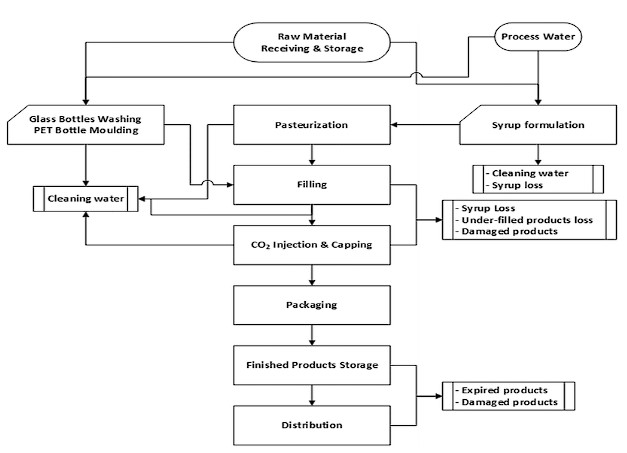

Soft Drink Manufacturing Flow Chart

1. Clarifying and Processing the Water

When it comes to the production of soft drinks, the water that’s used for production should have no impurities. That’s why suspended particles and bacteria are normally removed using a series of water treatments.

The first process is commonly referred to as clarification. Clarification aims to separate any suspended particles or matter from the water. During the process, flocs are mixed into the water to absorb suspended particles.

After the clarification process separates the flocs or suspended particles from the clear water, the water will go through filtration and disinfection.

The water will go through various filters that are made up of different materials and pore sizes. Once the flocs are completely removed, a small amount of chlorine is added to kill any remaining bacteria or parasites. After a few hours, the water is then dechlorinated using an activated carbon filter.

2. Syrup Formulation and Pasteurization

Once all the ingredients are ready for production, the manufacturers will focus on mixing all the ingredients together. The flavor concentrates and sugar are mixed into a tank, and the syrup will go through a heat treatment process called pasteurization.

Pasteurization will help kill any harmful microbes and extend the shelf life of the syrup. Shortly after, mixing equipment is used to carefully combine the syrup and water.

3. Carbonation & Filling tonight

After all the ingredients are properly processed and combined, the manufacturers will add the carbonated water to the mixture and start the filling or bottling process. Carbonated water is the main ingredient of soft drinks, and as you might already know, it adds that special fizz that we all see through plastic or glass soda bottles.

4. Packaging and Distribution

After the bottled or canned sodas are put into containers, the manufacturers will then pack them into cartons or other types of packaging. The manufacturers will then ship them to warehouses or directly to a variety of distributors, most of which are merchants.

Once you fully understand the manufacturing process of soft drinks, you will be able to produce and perfect your own soft drinks. But how can you produce, package, and distribute your own soft drinks if you don’t have your own working facility or set of equipment?

Getting your own manufacturing plant or equipment for production isn’t necessarily a good idea, especially if you don’t have a considerable amount of capital or resources to work with. It can become much riskier and more expensive once you start to invest in different assets for the production run of your products.

That’s why you’ll want to partner with a beverage contract manufacturer or co-packer instead. With the help of a beverage contract manufacturer, you will have less time to worry about your production costs and will be able to scale your soft drink business much more efficiently.

Ready to find the right co-packer? Let’s dive into the list!

Top Soft Drink Manufacturers for Your Beverage Product

Here are some of the top soft drink manufacturing companies that you might want to consider. Just know that there are lots of great drink manufacturing companies out there, so it’s all about finding the right fit for your product and business.

Or, keep reading:

1. Pack Labs

Pack Labs excels at small-batch beverage co-packing and drink manufacturing and has been guiding fledgling brands to commercial success. Their primary focus is on wellness and wellness-based products, which use functional and responsible ingredients.

Through this contract manufacturer, small and large businesses will be able to develop wellness-based goods that revolutionize and redefine categories at their custom facility. Apart from small-batch co-packing and manufacturing, Pack Labs also shines at product development and brand strategizing, making them a go-to for newer companies looking to put their best foot forward in the beverage business.

Services:

- Canning, bottling, and boxing

- Warehousing

- Product development

- Supply chains

Product Types:

- Beer, wine, and cider

- Ready-to-drink beverages

- Flavored malt beverages

Specialty product capabilities: Not specified

Location: Downingtown, PA

2. California Custom Beverage LLC

With over 30 years’ worth of experience in the carbonated beverage industry, California Custom Beverage strives to bring quality, natural products to the private-label market.

In addition to their production lines for non-alcoholic beverages, they also manufacture other beverage products such as beer and cider. With access to exclusive Chinese glass suppliers, California Custom Beverage is able to provide private label brands with unique and economical bottles.

Services:

- Private label manufacturing

- Contract packaging

- Contract manufacturing

- Ingredient sourcing

Product Types:

- Carbonated beverages and other non-alcoholic drinks

- Beer and cider

- Still water

Speciality Product Capabilities: Not specified.

Location: Los Angeles, CA

3. Green Mountain Beverage

Green Mountain Beverage offers a wide range of quality services. From product and research development to packaging services and distribution, the company is fully equipped to meet all the needs of new and growing beverage brands.

As one of the most reliable end-to-end supply chain services, Green Mountain Beverage strives to provide customers with the highest level of production knowledge and expertise.

Services:

- High-speed canning and bottling

- Kegging and cellaring

- Cold block and tunnel processing

- Supply chains (procurement, warehousing, shipping)

- Product development (vendor sourcing, pilot scale production, etc.)

- QA/QC and laboratory services

Product Types:

- Beer, wine, and cider

- Carbonated beverages

- Ready to drink beverages

- Flavored malt beverages

Specialty product capabilities:

- Organic

- Gluten-free

Location: Middlebury, VT

4. Great Soft Drink Manufacturing Company

This soft drink manufacturer provides a wide range of services, including co-packing, private labeling, and in-house laboratory testing. The company also offers warehousing and other fulfillment services with the help of its 425,000-square-foot facility.

It delivers ultra-premium products through sustainable packaging and responsible co-packing processes.

Services:

- Beverage formulation and canning

- Pasteurization and batching

- Can sleeving and laser encoding

- Carbonation and nitrogen dosing

- Shrink sleeving

- Co-packing and private labeling services

- Contract manufacturing

- Hot and cold fill

- Liquid blending

- Ingredient sourcing

- TTB services

- Supply chain management

- Packaging solutions (4-24 packs)

Product Types:

- Variety of alcoholic and non-alcoholic canned beverages

- Spirits

- Vintners

- Sugar brew

- Malt beverages

- Teas

Specialty product capabilities:

- Dairy-free

- Allergen-free

- Organic certified

- Kosher

- Gluten-free

Location: Indiana

5. Great Soft Drink Manufacturing Company

This company was founded in 1942 as a bottling company, but they offer services in manufacturing and other beverage-related needs. With their expertise in tea, energy drinks, and ready-to-drink beverages, as well as their additional services for ingredient sourcing, can sizing, tunnel pasteurization, and more. It’s also worked with brands such as 7UP and RC Cola.

Services:

- Contract manufacturing

- Private label manufacturing

- Contract packaging

- Bottling

- Ingredient sourcing

- Tunnel pasteurization

- Cold fill

- Can sizing

- Liquid nitrogen dosing

- Register film shrink wrap

Product Types:

- Energy drinks and other carbonated beverages

- Non-carbonated beverages

- Organic certified beverages

- Functional beverages

- ready-to-drink beverages

Speciality Product Capabilities:

- Kosher

- Gluten-free

- Organic

Location: Oregon

6. Great Soft Drink Manufacturing Company

This co-manufacturer makes carbonated and ready-to-drink beverages for mid to large businesses. They provide brands with different aluminum can options, including specialty coatings and sleek sizes.

In addition to their co-packing offerings, they help connect brands to other partner services such as marketing, consultation, and legal services. This company only uses pure, natural ingredients.

Services:

- Contract manufacturing

- Contract packaging

- Private label manufacturing

- Storage and logistics support

- Tunnel pasteurization

- Forced carbonation

- Ingredient sourcing

- Particulate and plate filtration

Product Types:

- Sodas & tonics

- Energy drinks

- Flavored seltzer

- Teas and coffee

- Distilled spirits cocktails

- Wine, beer, and cider

- Still water

Speciality Product Capabilities: Not specified.

Location: Minnesota

7. Great Soft Drink Manufacturing Company

This soft drink manufacturer is a family-owned and managed beverage company specializing in authentic craft sodas. They use the finest natural ingredients for production and custom craft every flavor they create in small batches. Besides carbonated beverages, they are also capable of producing kosher and gluten-free products as well.

Services:

- Contract manufacturing

- Private label manufacturing

- Contract packaging

- Ingredient sourcing

- Wholesale

Product Types: Carbonated beverages (craft sodas)

Speciality Product Capabilities:

- Kosher

- Gluten-free

Location: Colorado

8. Great Soft Drink Manufacturing Company

This manufacturing company primarily co-packs organic ready-to-drink beverages in glass bottles and aluminum cans. They aim to make and deliver authentic probiotic beverages like kombucha, kefir, and niche beverages. The company is capable of partnering with regional and national beverage brands.

Services:

- Fulfillment services

- Contract packaging

- Contract manufacturing

- Private label manufacturing

- Ingredient sourcing

- Research and development services

- Warehousing and logistics

Product Types:

- Probiotic beverages (kombucha, kefir, jun, etc.)

- Beer and cider

- Sparkling and still water

- Carbonated and non-carbonated beverages

- Functional beverages

- Prebiotic beverages

Speciality Product Capabilities:

- Organic

- Kosher

Location: Colorado

How to Start a Soft Drink Company

Starting a soft drink company from scratch can be a challenge. Apart from the development and production of your products, you will also need to plan and carefully consider your potential sales channels as well as initial funding options.

Let’s review!

1. Identifying your Target Market

Before you start your own soft drink company, it’s important that you first identify and analyze your target market. How will you sell your products? Will you sell directly to retailers or are you planning to have your own direct-to-consumer business?

Make sure to analyze each sales channel so you will know how to manage and market your business properly. Planning your potential sales channels will also enable your company to become more profitable in the long run.

2. Conceptualization & Formulation of Your Product

Start by testing your product on a small scale. Work your way up from the basics and then move on. Remember to keep your budget in mind while you create and formulate your product. Aim to make something that will make your customers come back for more–and only put the best version of your product in front of your target audience.

Of course, your formula is just as important as your recipe. This stage is about finding and combining ingredients in the right proportions to create the perfect food product recipe for taste and texture. A good formula can decrease production time, help ensure the product’s quality, and is just necessary for any large-scale beverage manufacturing.

3. Find Financing If Needed

In order to build your own soft drink business, you need to know where your capital will come from. Will it come from your savings? Do you need investors? Or are you going to try to apply for a bank loan?

Needless to say, you’ll most likely need to know how to raise additional outside capital for your company because CPG businesses are, without a doubt, capital-intensive. Although it’s not necessary to take on investors to make your brand successful, having multiple sources of funding will allow you to scale–and see profit–much faster.

4. Partner with a Soft Drink Manufacturing Company

We may sound like a broken record regarding this step, but having a great manufacturing partner is the key to a successful soft drink brand. Manufacturers can help with the entire production of your beverage product by offering services like:

- Research and development

- Recipe development, formulation, and reverse engineering

- Ingredient sourcing

- Product packaging & labeling

- Storage and warehousing

- Commercial test runs

- Tasting & recipe experimentation

- And any more!

Fortunately, finding the right manufacturing partner is a breeze with PartnerSlate’s matching marketplace…rather than spending months (or years) doing extensive research and making cold outreach.

PartnerSlate offers a huge network of manufacturers already pre-screened and organized by capacity and capability. All you have to do is upload your project details and you’ll be matched with qualified manufacturers that offer the services, volume, and pricing you need.

5. Consumer Testing & Marketing

Consumer testing is critical when launching a new product. Testing looks at the physical elements like consistency and appearance, sensory features like taste and smell, and design features of the packaging. Brands need feedback to determine if their product is acceptable and if further modifications need to be made.

You want to create a recognizable soft drink brand in stores, on shelves, online, and wherever else you sell your product. So before launching, develop a sales and marketing plan when marketing your beverage product.

Take advantage of social media and start promoting your beverage on social media channels. You can contact and collaborate with influencers to promote your beverage to reach your intended audience.

6. Registering & Legal Protection

Your soft drink company must have the proper license and permit to operate legally. Don’t forget about business insurance either; the last thing you want is a lawsuit.

Make sure to apply for trademarks or other intellectual property rights to protect the name, logo, marketing ideas, and other intangible assets of your company. Once you’ve registered your assets, you will be able to prevent other companies from further imitating the ideas you have in your business.

7. Launch!

When your soft drink is ready to hit the shelves, make sure you’ve got all your ducks in order:

- Your contract manufacturing partner has made a tasty and nutritious product marketable to consumers.

- Your creative team has made a product design that is recognizable and easy to remember.

- The marketing department has spent time building a campaign to help with the launch and attract consumers.

- Sales have lined up buyers so the product can scale when launched.

Read more on how to get your food or beverage product from idea to launch.

FAQs on Soft Drink Manufacturing

Who is the biggest producer of soft drinks?

In the United States, PepsiCo. Is the largest soft drink company and producer followed by other beverage giants such as Coca-Cola Co. and Heineken.

How many companies are in the soft drink industry?

As of 2023, there are 386 soda companies in the United States. The major leading companies in the U.S. are Coca-Cola Co., Pepsi.Co, and Keurig Dr.Pepper Inc.

What are the top soft drink companies in the world?

The top soft drink companies in the world are PepsiCo., Unilever, and Coca-Cola Co.

Partner with the Best Soft Drink Manufacturer

Finding the best manufacturing company for your beverage brand can certainly be a tough task. All the soft drink contract manufacturers and co-packers we’ve mentioned so far are great–but there are plenty of other beverage manufacturing companies out there to consider.

To make the search process easier, let PartnerSlate do the work for you.

With PartnerSlate, you will be able to take your products to store shelves faster!