- Food Startup Funding: Do you need investors to build a successful food or beverage business? - February 29, 2024

- Explaining Food Certifications & Labeling: Organing, Non-GMO, Halal, Kosher, & More! - February 29, 2024

- Explaining the Meaning of MOQ - February 29, 2024

High pressure processing (HPP) is a non-thermal pasteurization technique that has gained widespread recognition in the food industry. This eco-friendly method effectively eliminates harmful microorganisms and extends shelf life to help ensure product quality and safety.

If you have a food or beverage product that requires HPP, or if you’re looking for a potential co-man or co-packer that offers these services, it’s helpful to first understand the complexities of the technology. This article will review what high pressure processing is, how it works, and how to determine if you’ll need it for your food brand.

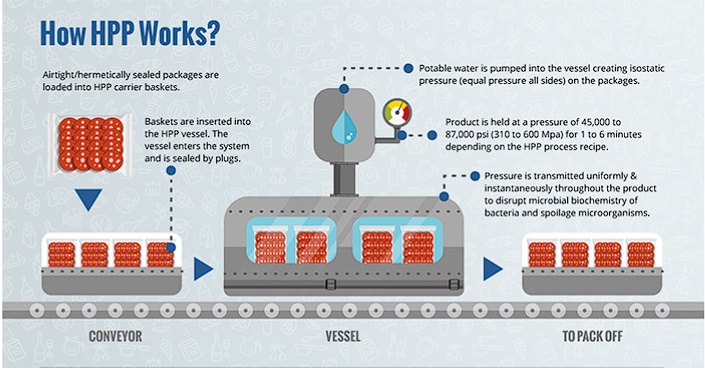

How Does HPP Work?

High pressure processing involves subjecting packaged food products to pressures ranging from 3000 to 6000 bar in water-filled pressure vessels. The high pressures disrupt the cellular structure of microorganisms present in the food, effectively inactivating them without the need for high temperatures that can affect taste, color, texture, and nutritional content. The sterilization process occurs within the product’s final packaging, eliminating the risk of contamination post-processing, and ensuring the integrity of the food’s quality and safety.

High pressure processing is compatible with various packaging materials, including plastic, glass, and metal containers. This versatility enables you to cater to your customers’ preferences and your product’s unique requirements. However, it’s important to ensure that the chosen packaging material can withstand high pressure without collapse or rupture.

Below is a step-by-step rundown of the HPP process:

- Preparation of food products: Before HPP, food products must be appropriately packaged in a flexible, water-resistant, and pressure-resistant material.

- Loading the HPP machine: Place the packaged food products into the pressure vessel, or pressure chamber, of the HPP machine. The vessel can accommodate various shapes and sizes of food products and packages, but loading does require careful arrangement to maximize the load capacity.

- Filling the pressure vessel with water: Once the products are loaded, the pressure vessel is filled with water. This water acts as the pressure transmission medium and ensures even pressure distribution on all surfaces of the packaged products.

- Pressurization: After sealing the pressure vessel, the HPP machine will begin to increase pressure by pumping more water into the chamber. This high pressure is what inactivates microorganisms, enzymes, and other spoilage agents in the food.

- Holding time: Maintain the desired pressure level for a predetermined holding time, typically ranging from 1 to 5 minutes, depending on the food product and desired shelf life extension. This holding time ensures the effective inactivation of the targeted microorganisms and enzymes.

- Depressurization: After the holding time, the HPP machine releases the pressure inside the chamber rapidly, usually within a few seconds. This rapid depressurization prevents damage to the food products and helps maintain their texture, color, and nutritional properties.

- Unloading and storage: Once the pressure has returned to atmospheric levels, unload the treated food products from the pressure vessel. They are now ready for storage, distribution, or further processing, as needed.

What Food and Drink Products Use High Pressure Processing?

A wide range of food and beverage products can benefit from HPP from juices to sauces to ready-to-eat meals. By preserving nutritional value and flavor profiles, deli meats, fresh fruit and vegetable products, and various dairy items such as yogurts and cheeses are also known to benefit greatly from this method. High pressure processing is often popular for processing guacamole and other avocado-based products since it helps maintain their freshness and taste.

In the beverage industry, HPP has made significant strides as well–cold-pressed juices, coconut water, and flavored milks experience a longer shelf life and enhanced nutritional content through this innovative method. The cold-brew coffee market has also embraced HPP, ensuring the preservation of flavors while deterring mold and maintaining freshness.

Below is a list of more foods that can be treated using high pressure processing:

Fruits and vegetables:

- Fresh fruit juices, such as orange, apple, and grape

- Smoothies and fruit purees

- Fresh-cut fruits, such as melons, pineapples, and mangoes

- Fresh-cut vegetables, including carrots, celery, and lettuce

- Fruit and vegetable-based sauces, salsas, and dips

Meat and poultry products:

- Deli meats, such as ham, turkey, and roast beef

- Raw or marinated meats, like beef, pork, and chicken

- Sausages and hot dogs

- Cooked meat products, including ready-to-eat meals

- Pâtés and meat spreads

Seafood products:

- Raw or cooked shellfish, such as shrimp, crab, and lobster

- Fresh or smoked fish, including salmon, tuna, and trout

- Fish filets and steaks

- Ready-to-eat seafood-based meals

Dairy products:

- Liquid products, such as milk, cream, and yogurt drinks

- Cheese, including fresh and soft varieties, like mozzarella and feta

- Yogurt, including Greek and traditional styles

- Dairy-based desserts, like custards and puddings

Ready-to-eat meals:

- Sandwiches and wraps

- Salads and prepared vegetable dishes

- Soups and stews

- Heat-and-eat entrees, such as pasta dishes and casseroles

Wet salads and dips:

- Coleslaw and potato salads

- Hummus and guacamole

- Salad dressings and vinaigrettes

Baby food:

- Fruit and vegetable purees

- Meat and fish-based purees

- Combination meals and toddler snacks

Searching for the Perfect Co-packer?

HPP vs Heat Pasteurization

Heat pasteurization is a widely used thermal method for prolonging the shelf life of food products and ensuring their safety. Instead of the pressure used in HPP, it involves heating food to specific temperatures for predetermined lengths of time in order to destroy harmful pathogens and spoilage-causing microorganisms.

While this method has proven efficient in improving food safety and preserving products, it comes with its drawbacks. Heat pasteurization can cause changes in the product’s taste, color, texture, and nutritional content, often resulting in a less fresh and less appealing final product.

If your goal is to differentiate your brand by offering clean-label, high-quality, and health-focused products, investing in HPP can be a game-changer for your food business in terms of capturing a broad consumer base and setting yourself apart in the competitive marketplace. Still, heat pasteurization remains effective and accessible for many food products.

High Pressure Processing Effects & Benefits

Cold Process

Embracing the benefits of HPP as a food business owner means appreciating its cold process. This means that no additional heating or cooling is necessary, making it a more sustainable and efficient option for food processing. It can ultimately lead to energy savings and a reduced carbon footprint for your business.

Removing Microorganisms

By effectively eliminating pathogenic microorganisms like listeria, E. coli, and salmonella, HPP significantly reduces the risk of foodborne illnesses. This ensures a higher level of food safety for your customers and can enhance your brand reputation.

Extended Shelf Life

High pressure processing ensures food safety and also extends the shelf life of products that have already been pasteurized, thanks to the further inactivation of any remaining microorganisms. Longer shelf life allows for improved inventory management, reduced waste, and better distribution capabilities.

Preserves Flavor, Color, & Texture

One of the major advantages of HPP over traditional heat pasteurization methods is its preservation of natural flavor, color, and texture in food products. This delivers a fresher taste to consumers which can lead to increased customer satisfaction and brand loyalty.

Reduced Environmental Impact & Production Costs

HPP’s cold process and minimal use of chemicals lend to a reduced environmental impact and lower production costs in comparison to traditional methods. This environmentally friendly method allows your brand to appeal to eco-conscious consumers, while simultaneously minimizing production expenses, which is nice for your bottom line.

Maintains Nutritional Content

HPP’s ability to process food without heat is crucial for preserving the valuable nutrients in your products. As health-conscious consumers increasingly demand nutrient-rich, clean-label products, this technology offers a competitive advantage in meeting these expectations.

Drawbacks of HPP

Before integrating high pressure processing into your production process, it’s essential to consider some of its limitations to ensure its suitability for your products.

Equipment Cost

The initial investment in HPP equipment can be steep for some businesses, particularly for small-to-medium-sized enterprises. High-quality HPP machines, which ensure optimal results, often come with a hefty price tag.

To mitigate this challenge, food business owners can explore partnering with a reliable contract manufacturer that already owns and operates the technology, thus reducing upfront costs and still benefiting from the method’s advantages.

Operating Costs

High pressure processing operating costs can be higher compared to hot fill and other pasteurization methods due to factors such as energy usage, maintenance, and the need for skilled operators.

However, it’s essential to weigh these costs against the increased shelf life, enhanced food safety, and overall improvement in product quality. In many cases, these benefits more than justify the extra cost, making HPP a potentially very valuable long-term investment.

Limited Availability

Due to the high costs and specialized equipment involved, HPP services may not be widely available in all regions. This can be a hurdle for food business owners looking to implement this technology.

Let PartnerSlate do the research and connect you with experienced co-packers and contract manufacturers in your region that offer HPP services. This will allow you to leverage their expertise without needing to invest in the equipment yourself.

Is High-Pressure Processing Safe?

HPP is considered a safe method for food processing since it effectively eliminates harmful microorganisms without changing the food product and doesn’t require the use of chemicals. This technology can help your products stand out in an increasingly competitive market where consumer awareness of ingredients and food processing techniques is on the rise.

However, it’s important to keep in mind that high pressure processing is not a one-size-fits-all solution since some food products may not be suitable for the high-pressure treatments. It’s helpful to work closely with HPP experts or specialized contract manufacturers to optimize the process for your specific products and ensure successful outcomes.

Find a Contract Manufacturer with High Pressure Processing Capabilities

High pressure processing is an effective and sustainable method for food processing that offers numerous advantages over traditional heat pasteurization. It ensures the safety and quality of food products while maintaining their natural flavor, color, texture, and nutritional content.

Whether you’re a food business owner looking to use HPP technology–or aren’t quite sure what processing your food or beverage product needs–PartnerSlate will help you find the perfect contract manufacturer with the required expertise and equipment.

PartnerSlate’s matching marketplace pairs you with high-quality production partners from an extensive network of food and beverage manufacturers and packagers. Simply start by creating a profile and listing your project. We’ll connect you with multiple manufacturers on our platform, which streamlines document sharing, communication, and onboarding–all in one place!