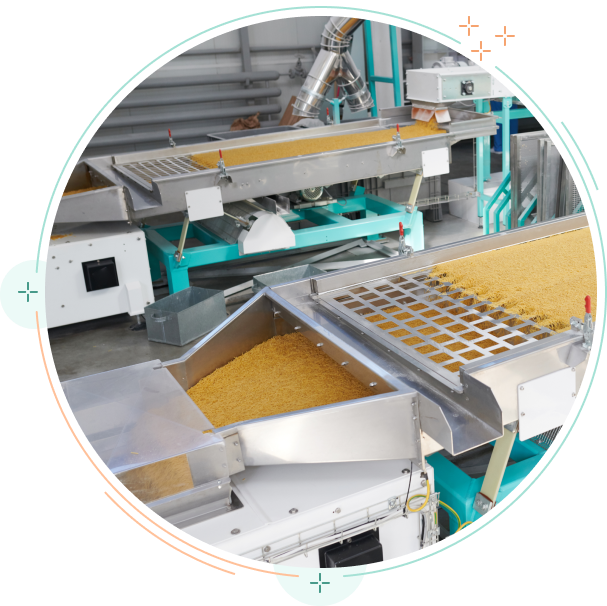

Find Your Next Dry Mix

Co-Packer in Days, Not Months.

PartnerSlate has 409 dry mix contract manufacturers and co-packers in our network, actively sourcing new projects. Whether you are a start-up or a Fortune 500 company, we can match you with high-quality production partners that fit your needs.

Our Manufacturers Specialize in:

- Baking Mixes

- Flour

- Baking powder

- Muffins Mix

- Pancakes Mix

- Waffle Mix

- Biscuits Mix

- Cake Mix

- Cookie Mix

- Brownie Mix

- Dessert Mix

- Pudding Mix

- Gelatin Mix

- Pie Crust Mix

- Bread Mix

- Pizza Dough Mix

- Soup Mix

- Gravy Mix

- Dip Mix

- Seasoning Mixes (tacos, chili, or pasta)

- Drink Mix

- Hot cocoa mix

- Instant coffee

- Flavored Drink Mix

Most of our manufacturers are certified and audit-ready:

• Organic

• Non-GMO

• Fair Trade™

• Gluten-Free

• Kosher

• Parve

• Soy-Free

• Dairy-Free

• Sugar-Free

• Vegan

• Allergen-Free

• SQF

• USDA

• FDA

• GMP

Experienced working with Whole Foods Markets, Costco, Trader Joe’s, and many other major retailers.

They can package in a variety of formats, including:

• Pouches

• Aluminum Foil Pouches

• Foil Lined Bags

• Glass Jars

• Flexible Packaging

• Paper Bags

• Plastic Tubs or Containers

• Cardboard Boxes

• Vacuum-Sealed Bags

• Biodegradable and Eco-Friendly Packaging

• Bulk Packaging

Trusted By Innovative Brands

I found plenty of manufacturers. The platform was really easy to use and filter – it provided me with options that I hadn’t discovered before.

– Jamie’s Farm

Looking For Your First Co-Manufacturer?

Finding a dry mix co-packer involves a series of steps to identify, evaluate, and select a suitable partner for your dry mix production. Here’s a guide to help you in the process:

1. Define Your Requirements:

Clearly outline your product specifications, including ingredients, packaging, and production quantities. Identify any certifications or quality standards required for your dry mix item. If you are able to know what specific equipment is needed, this will help narrow your search.

Hint: If you need an idea of what questions co-packers and co-mans will ask, fill out a project intake form on our website. It is free to fill out and will help prepare you for your manufacturer search! Get started by creating a free account here.

2. Research Potential Co-Packers:

Use online resources, industry directories, and trade associations to identify potential co-packers. Look for co-packers with experience in dry mix production and a good reputation. You will also want to make sure that your quantities align with their minimum order quantities.

Want to skip this step? Get your project listed on PartnerSlate and have our vetted manufacturers reach out to you.

3. Industry Associations and Networks:

Connect with food industry associations or networks. They often have directories of co-packers or can provide recommendations.

4. Attend Trade Shows:

Attend relevant trade shows or expos in the food industry where you can meet potential co-packers. Trade shows provide an opportunity to see their capabilities and discuss your needs face-to-face.

5. Online Platforms and Directories:

Utilize online platforms and directories that connect businesses with co-packers in the food industry.

6. Network in the Industry:

Connect with professionals in the food industry through networking events, forums, and social media. Ask for recommendations or insights from those who have experience in co-packing.

7. Request for Proposals (RFPs):

Prepare a detailed request for proposals outlining your requirements and send it to potential co-packers. Include information about your dry mix project, production volumes, quality standards, and any other relevant details. PartnerSlate can also streamline this process for you.

8. Visit Facilities:

If possible, visit the facilities of potential co-packers to assess their capabilities, hygiene standards, and overall suitability.

9. Check References:

Ask for and check references from other companies that have worked with the co-packer. Inquire about their experiences and satisfaction with the co-packer’s services.

10. Negotiate Terms and Contracts:

Once you’ve identified a suitable co-packer, negotiate terms, pricing, and production schedules. Ensure that all aspects are clearly outlined in a comprehensive contract.

11. Quality Control:

Establish clear quality control standards and procedures to ensure that your dry mix items meet the desired specifications.

12. Legal and Regulatory Compliance:

Verify that the co-packer complies with all necessary legal and regulatory requirements for food production.

13. Start with a Trial Run:

Consider starting with a smaller production run to assess the co-packer’s performance and the quality of the produced snacks.

It’s essential to conduct thorough due diligence to ensure that the co-packer aligns with your business needs and values. Each co-packer may have unique capabilities, specialties, and terms, so finding the right fit for your specific frozen meal production requirements is crucial.